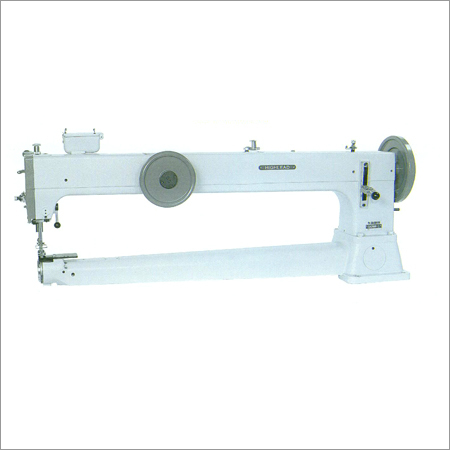

High Speed Post Bed for Shoe Manufacturing

Product Details:

Product Description

PRODUCT ADVANTAGES:1) Overload clutch system for the sewing hook

2) The operator can change to the correct needle plate inserts for different trimming margins

(for sub-classes 725/04-726/05) or thread sizes 80/3-15/3 synthetic as required

3) Automatic hook lubrication

4) Accurate and simple adjustment of the needle guard

5) Integrated servo drive provides more leg room

6) Very simple operation due to new, clearly-arranged BDF-S1 control panel in combination with the new control concept

7) Flash software update without changing the E-Prom and opening the control box

8) Optional: Perbunan-coated roller presser for highly sensitive leather surfaces (Part set No. 91-263 108-91)

ADDITIONAL EQUIPMENT:

-725/04 =

Edge trimming mechanism - bottom driven.

-726/05 =

Edge trimming mechanism - top driven.

-900/81 =

Electromagnetic thread trimmer.

Thread end approx. 10 mm.

-910/15 =

Automatic presser foot lift, electropneumatically

controlled, with additional knee lever for intermediate

foot lift.

Air filter/lubricator required.

(Only in connection with -900/..).

-911/35 =

Automatic backtacking mechanism with additional

push-button for intermediate backtacking.

(With -900/81-910/15 only).

-940/02 =

Dome-shaped needle plate for PFAFF 571 – 591

- Standard on machines without a thread trimmer

- On machines with a thread trimmer, the thread

trimming block must be removed.

Loosen only two Allen screws.

Bobbin thread monitor with stitch counting is standardNew, easily adjustable thread trimmer with short thread ends, for thread sizes up to 15/3 synthetic

Other Products in 'Home Sewing Machine' category

GST : 07AAAFH1736L1ZF

|

|

|

|

HCA GARMENT MACHINERY PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |